Pioneering hydrogen cargo bikes with swappable H2 cylinders

The Challenge

Urban logistics and last-mile delivery in European cities face significant challenges that impact sustainable mobility. Electric cargo bikes offer a promising solution by reducing traffic congestion, lowering emissions, and creating local jobs. However, these bikes have several limitations: heavy batteries, scarce fast-charging stations, and technological constraints. As a result, delivery workers must stop frequently to charge their bikes, slowing operations and reducing efficiency.

Meanwhile, freight vehicles contribute up to 30% of urban traffic emissions, intensifying city pollution. To address this, there is growing interest in hydrogen fuel cells as an alternative to large battery packs for cargo bikes. Hydrogen fuel cells offer a longer range, reduced weight, and faster refuelling. However, integrating this technology into small vehicles presents its own challenges.

Key issues include developing a compact and reliable hydrogen fuel cell for cargo bikes, designing a system for quick cartridge swaps without large refuelling stations, and ensuring safety and ease of use. Additionally, gaining the support of logistics companies, city officials, and end users is essential to proving that hydrogen-powered cargo bikes are a practical and beneficial solution.

The Solution

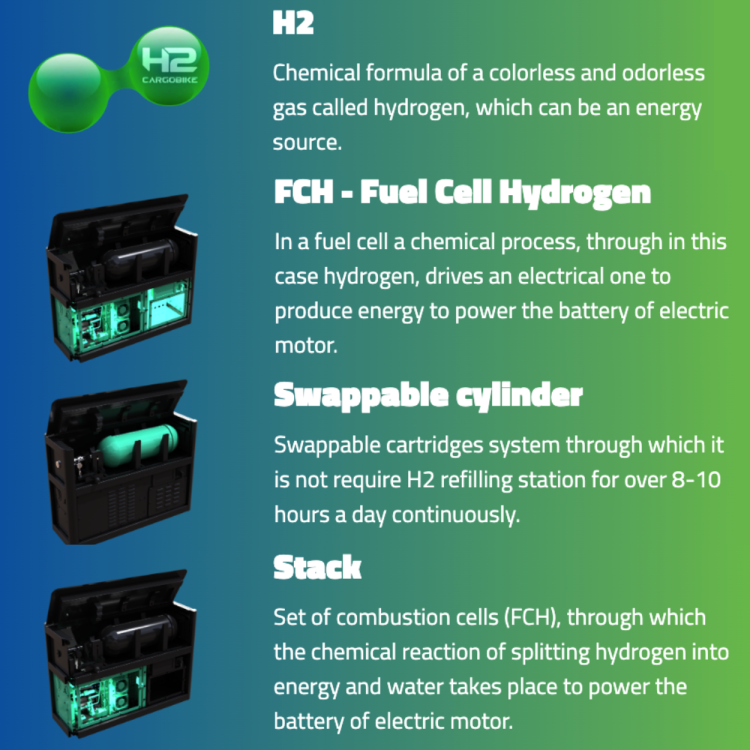

To overcome the challenges of heavy batteries and limited charging infrastructure, the H2 Cargo bike introduced a hydrogen-powered 4-wheel cargo bike featuring an ultra-lightweight carbon fibre frame in Padua, Italy and Donostia-San Sebastián, Spain. This innovative vehicle is designed to carry loads of over 150 kg while maintaining high operational efficiency through Fuel Cell Hydrogen (FCH) swappable cylinder technology.

Instead of relying on large battery packs, the cargo bike uses a compact hydrogen fuel cell stack. Hydrogen stored in a tank is injected into the FCH stack, where it reacts with oxygen from the air. This chemical reaction produces electricity and water as a byproduct, which powers the bike’s electric motor while emitting only water vapor. The process makes the system sustainable and environmentally friendly.

The swappable cylinder technology is a key part of the solution. It eliminates the need for fixed refuelling stations by allowing quick and easy exchange of hydrogen cartridges. This means that delivery operations can continue without long stops for charging or refuelling, significantly improving efficiency and reducing downtime.

By integrating a lightweight design with a clean, renewable energy source, the hydrogen-powered cargo bike addresses the limitations of current electric cargo bikes. It promises faster refuelling and a reduction in urban congestion and emissions, paving the way for a more sustainable and efficient last-mile delivery system.

Making an impact

The innovation successfully piloted in Padua and Donostia-San Sebastián, by engaging leading EU cargo bike operators, TRICLO’ and TXITA, which collectively employ over 30 bike messengers.

Over two months, more than 300 km were driven and over 100 deliveries completed in diverse urban environments, with feedback gathered from at least 10 operators who tested the bikes.

A comprehensive safety analysis was conducted, resulting in a dedicated usage protocol and training tailored to each country’s regulations and specific bike parking areas.

Overall, the solution enhanced confidence in hydrogen technologies, promoted cyclologistics as an efficient last-mile solution, and demonstrated the feasibility of testing H2 vehicles without costly HRS infrastructure.

The innovation gained significant visibility by participating in major events in Padova, Bilbao, and the Barcelona Smart City EXPO, and received local press coverage. Additionally, a patent for the swopping technology was submitted following freedom to operate verification.

Lessons learnt

The use case has demonstrated that increasing onboard electricity capacity and simplifying the cartridge change process can significantly enhance operational continuity. By storing more electricity on board and enabling quick cartridge swaps, vehicles can operate without recharging downtime. This advancement not only supports extended working hours for delivery services but also enables new applications in sensitive logistics sectors such as the food and pharmaceutical cold supply chain.

The additional energy available on cargo bikes can be used to power refrigeration systems, ensuring that perishable goods remain at the correct temperature during transit. This adaptability highlights how hydrogen-powered cargo bikes can address diverse urban delivery needs, from standard parcels to temperature-controlled products, by leveraging increased electrical capacity.

Another key challenge is the lack of clear regulations for small quantities of hydrogen. The absence of a standardised regulatory framework makes it difficult for local municipalities to confidently approve and implement hydrogen applications. In countries such as Spain and Italy, regulations vary significantly, creating uncertainty across European regions for the deployment of hydrogen solutions. Addressing these regulatory gaps and establishing harmonised guidelines will be essential for expanding the use of hydrogen-powered vehicles in urban environments.